Under the background of "energy saving and environmental protection", the energy efficiency standard of air-conditioning is continuously upgraded. As the core component of the air conditioner, compressor plays a decisive role in the performance of the air conditioner. Therefore, the technical progress is hard and fast, and the new material with high quality can achieve twice the result with half the effort. With its excellent performance, NdFeB magnet has become important components in the variable-speed drive (VSD) air compressor industry, and has become an absolutely dominant product in determining the performance of variable frequency compressor.

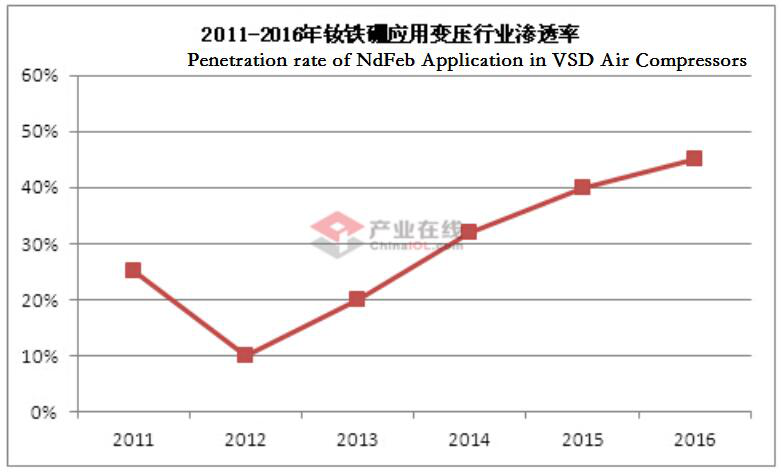

However, NdFeB material on this road of VSD is also after many ups and downs. According to the industry online data statistics, as of the end of 2016, Penetration rate of NdFeB material in the inverter air conditioner compressor industry is only about 45%, up to today has not yet reached 50%, so the road is full of bitter tears.Penetration rate of NdFeB in variable frequency drive air compressor industry in 2011-2016 years (%)

Before 2008, only a small amount of NdFeB material was used in the inverter compressor industry in china. With the requirements and development of energy saving and environmental protection in the international refrigeration industry, the scale of inverter air conditioner market is expanding rapidly. Meanwhile, the application and development of rare earth permanent magnet in the inverter compressor has ushered in an opportunity. Rare earth material is superior in performance and price advantage, so it is widely used in air conditioner variable frequency compressor. Its application not only improved the energy efficiency of the inverter compressor, but also made it more environmentally friendly, which laid the indispensable position of NdFeB in variable frequency compressor.

2009-2011 years, it is the golden age of use of NdFeB in the inverter compressor industry. It is reported that thethe first half of 2008, high efficiency compressor shipments accounted for less than 10%, while the first half of 2009 is close to 50%. LG 2009 years after June, energy efficiency subsidies will be the original 4, 5 energy efficiency compressor into the 'limbo', the original 1, 2 energy-efficient compressor volume quickly became the leading products.

According to the online industry data showing, in 2011 years compressor annual sales of 30240 thousand units, the average amount of rare earth permanent magnet used about 100 grams is calculated by a 1.5 HP compressor, NdFeB magnet in 2011 cold compressor using up to 2000 tons. The outbreak of the demand for rare earth metals business in a short period of 2 years, 3 earned pours.

In 2011, the market encouraged the rare earth permanent magnet enterprises to replace ferrite with NdFeB magnets. However, in the prospect of unlimited good, rare earth prices skyrocketing (the highest increase of 715.79% metal neodymium dysprosium metal, rose as high as 429.41%), the replacement of the road to an abrupt end, great expectations also is illusion.

As rare earth prices continue to rise, most of the compressor companies can not afford the high cost, and did not find new alternative materials, had to re-use of ferrite magnet. New rare earth variable frequency compressor production line was forced to stop and invest to start ferrite production line. This unrest is not only domestic compressor enterprises can not afford, foreign enterprises are equally difficult to bear. Data showing that, a domestic enterprises in July 2011 rare earth inverter compressor output of 200 thousand units, and by the end of the year, its output is only 5000 units.

The huge changes make the NdFeB magnets manufacturers, factories cut or stop production to deal with. From 2012 year October, most of the compressor enterprises have changed the rare earth production line to ferrite production line, and the total amount of rare earth permanent magnet in the 2012 cooling year is less than 1/10 compared with the 2011 cold year. Because only NdFeB magnets can work for 1,2 energy-efficient grade , ferrite can not reach the standard, which also give NdFeB magnets slim chance of survival.

In 2013, the implementation of the new energy efficiency standards for variable frequency air conditioners, so that the frequency conversion compressor using NdFeB has become a necessary condition, neodymium iron boron demand base reproduction. Into 2014, the frequency of air-conditioning production accounted for further increased to 52%, NdFeB magnets will increase the amount of access. In 2015, the total output of variable frequency compressor was 50010 thousand units, including 49460 thousand rotary frequency conversion units and 550 thousand scroll frequency conversion units. In 2015, the penetration rate of NdFeB was about 40%, and the annual consumption of NdFeB was about 4200 tons.

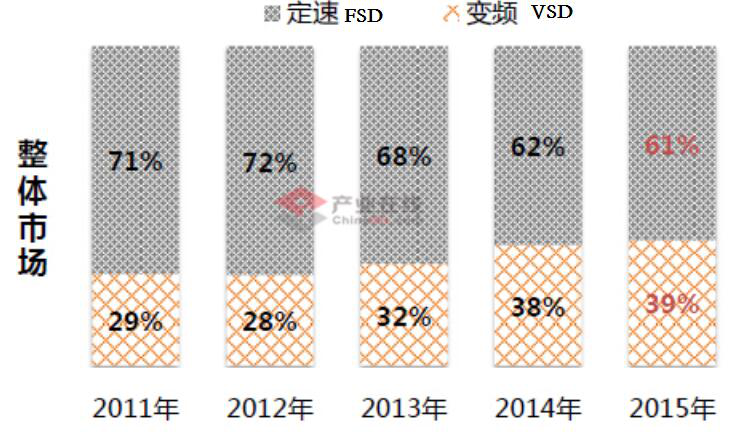

Development trend of fixed frequency conversion structure for household air conditioner in 2011-2015 years (%)